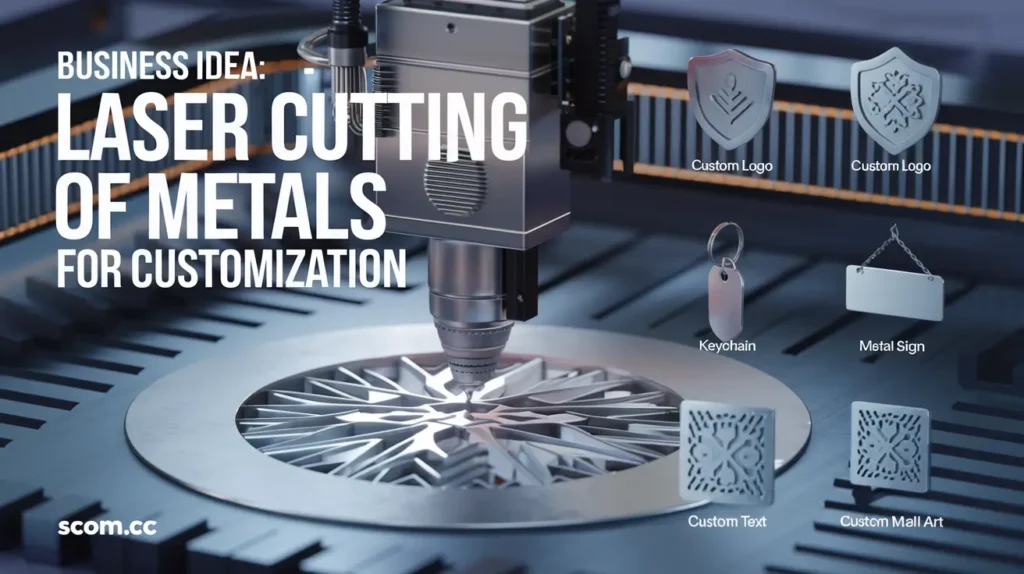

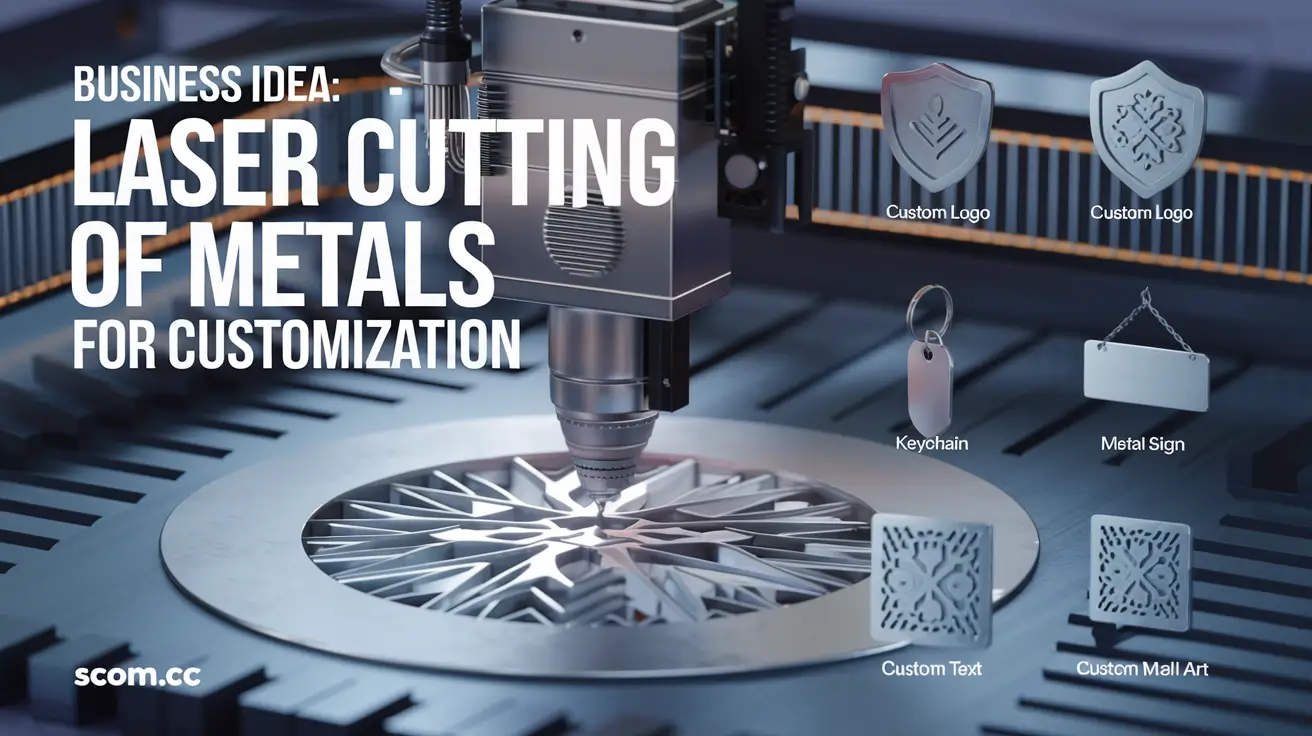

Business Idea Laser Cutting of Metals for Customization

- Business Idea Laser Cutting of Metals for Customization

- Introduction to Laser Cutting of Metals for Customization

- What Is Laser Cutting of Metals?

- Market Potential for Laser Cutting Services

- Initial Costs and Investment

- Benefits of Laser Cutting Services

- Challenges and Considerations

- Legal and Regulatory Aspects

- Marketing and Placement Strategies

- Future Trends and Innovations

- Conclusion

- Summary Table

-

FAQ

- What is laser cutting of metals?

- What are the initial costs for starting a laser cutting business?

- What are the main benefits of laser cutting services?

- What challenges might businesses face with laser cutting services?

- What legal and regulatory aspects should be considered?

- How can businesses effectively market their laser cutting services?

- What are the future trends in laser cutting of metals?

Business Idea Laser Cutting of Metals for Customization

Laser Cutting of Metals for Customization: A High-Precision Business Opportunity

Offer laser cutting services for metals, allowing the creation of customized and detailed products for industrial and commercial clients.

Introduction to Laser Cutting of Metals for Customization

The demand for precision in metalworking has grown significantly across various industries. From manufacturing to commercial artistry, the need for custom, detailed metal products is ever-increasing. Laser cutting technology offers a precise and efficient solution, allowing businesses to create intricate designs and shapes with unmatched accuracy. This article explores the concept of laser cutting for metals, its market potential, benefits, costs, and considerations for establishing a successful laser cutting service business.

What Is Laser Cutting of Metals?

Laser cutting is a technology that uses a focused laser beam to cut or engrave materials, primarily metals, with extreme precision. This process can create complex designs, custom shapes, and detailed engravings, making it ideal for various applications in industries ranging from automotive to jewelry making.

Key Components of a Laser Cutting System

- Laser Source: The core component that generates the laser beam. Common types include CO2, fiber, and YAG lasers.

- Cutting Head: Directs the laser beam onto the material with high precision.

- CNC Controller: A computer system that controls the movement of the cutting head and material, ensuring accurate cuts.

- Assist Gas System: Uses gases like nitrogen or oxygen to blow away molten material and improve cutting quality.

- Material Handling System: Automatically positions the metal sheets for cutting, reducing manual labor.

Market Potential for Laser Cutting Services

The versatility and precision of laser cutting make it a valuable service across various industries. The ability to create custom and detailed metal products opens up opportunities in both industrial and commercial sectors.

Target Markets

- Manufacturing and Fabrication: Companies that require custom metal parts, components, and prototypes.

- Automotive Industry: Custom car parts, detailing, and metal accessories.

- Construction and Architecture: Customized metal designs for building facades, railings, and structural elements.

- Jewelry and Artisans: Detailed engravings and custom metal designs for artistic and commercial purposes.

- Signage and Advertising: Precision cutting for metal signs, logos, and display pieces.

Initial Costs and Investment

Starting a laser cutting business involves a substantial investment in equipment and setup. However, the potential return on investment (ROI) can be significant due to the high demand for precision metal cutting services.

Cost Breakdown

- Laser Cutting Machines: Depending on the type and power, laser cutting machines can range from $20,000 to $500,000.

- Facility Setup: Includes costs for space, utilities, ventilation systems, and installation of machinery.

- Raw Materials: Ongoing costs for metal sheets, assist gases, and other consumables.

- Labor and Training: Costs associated with hiring skilled operators and providing training on machine operation and maintenance.

Benefits of Laser Cutting Services

Laser cutting offers numerous advantages, making it an attractive business opportunity for those looking to enter the metalworking industry.

Advantages

- High Precision: Laser cutting allows for intricate and detailed designs with minimal tolerance for error.

- Versatility: Capable of cutting a wide range of metals, including steel, aluminum, copper, and more.

- Efficiency: Faster cutting speeds compared to traditional methods, leading to increased productivity.

- Minimal Waste: The precision of laser cutting reduces material waste, making it a cost-effective solution.

- Customizability: Ability to create unique and personalized products tailored to client specifications.

Challenges and Considerations

While laser cutting services offer significant potential, there are challenges and considerations that businesses must address to ensure successful operation.

Common Challenges

- High Initial Investment: The cost of purchasing and setting up a laser cutting machine can be substantial.

- Maintenance and Repairs: Regular maintenance is required to keep the machines running smoothly, and repairs can be costly.

- Operator Skill Requirements: Skilled operators are needed to ensure accurate cuts and troubleshoot any issues with the machinery.

- Technology Updates: As laser cutting technology advances, staying up-to-date with the latest machines and software can be expensive.

- Competition: The growing popularity of laser cutting services means that businesses must differentiate themselves to stay competitive.

Legal and Regulatory Aspects

Operating a laser cutting service involves adhering to various legal and regulatory standards, particularly concerning safety and environmental impact.

Key Regulations

- Safety Standards: Compliance with occupational health and safety regulations to protect workers from laser hazards, including proper shielding and protective equipment.

- Environmental Regulations: Adherence to regulations concerning emissions, waste disposal, and energy usage.

- Material Handling Regulations: Proper handling and storage of metals and gases used in the cutting process to ensure safety and compliance with local laws.

- Zoning and Permits: Ensuring that the business operates in a properly zoned area and obtaining any necessary permits for industrial operations.

Marketing and Placement Strategies

Effective marketing and placement strategies are crucial for promoting laser cutting services and attracting potential clients. Building a strong market presence can help businesses reach a wider audience and drive growth.

Marketing Tips

- Showcase Precision and Quality: Highlight the precision and quality of laser cutting services in marketing materials.

- Target Niche Markets: Focus on industries and markets that require custom metalwork, such as manufacturing, automotive, and jewelry.

- Develop a Strong Online Presence: Utilize websites, social media, and online advertising to reach potential clients and showcase past projects.

- Offer Customization: Emphasize the ability to create personalized and unique products tailored to client specifications.

- Network with Industry Professionals: Build relationships with architects, designers, and manufacturers who may require laser cutting services.

Future Trends and Innovations

The laser cutting industry is continually evolving, with new technologies and trends emerging that can shape the future of the business. Staying informed about these developments can help businesses remain competitive and adapt to changing market demands.

Emerging Trends

- Increased Automation: Integration of robotics and automation in laser cutting processes to further improve efficiency and reduce labor costs.

- Advanced Materials: Development of new materials that can be cut with lasers, expanding the range of applications.

- Eco-Friendly Practices: Growing emphasis on sustainability, including energy-efficient machines and environmentally friendly materials.

- AI and Machine Learning: Use of artificial intelligence to optimize cutting processes, reduce errors, and improve overall productivity.

- Customization and Personalization: Increasing demand for personalized products, leading to more opportunities for custom laser cutting services.

Conclusion

Laser cutting of metals for customization presents a lucrative business opportunity for those looking to enter the metalworking industry. By understanding the market potential, managing initial costs, and addressing challenges, businesses can successfully establish and grow their laser cutting operations. With a focus on precision, quality, and innovation, this business model can meet the increasing demand for custom metal products across various industries.

Summary Table

| Aspect | Details |

|---|---|

| Service | Laser cutting of metals for customized and detailed products |

| Key Features | High precision, versatility, efficiency, minimal waste, customizability |

| Target Markets | Manufacturing, automotive, construction, jewelry, signage |

| Initial Costs | $20,000 to $500,000 for machinery, plus facility setup, raw materials, and labor |

| Benefits | High precision, versatility, efficiency, cost-effectiveness, customizability |

| Challenges | High initial investment, maintenance and repairs, operator skill requirements, technology updates, competition |

| Legal Requirements | Safety standards, environmental regulations, material handling regulations, zoning and permits |

| Marketing Strategies | Showcase precision, target niche markets, develop an online presence, offer customization, network with industry professionals |

| Future Trends | Increased automation, advanced materials, eco-friendly practices, AI and machine learning, customization and personalization |

FAQ

What is laser cutting of metals?

Laser cutting of metals involves using a focused laser beam to cut or engrave materials with extreme precision, allowing for the creation of custom and detailed metal products.

What are the initial costs for starting a laser cutting business?

Initial costs include $20,000 to $500,000 for laser cutting machines, plus expenses for facility setup, raw materials, and labor.

What are the main benefits of laser cutting services?

Benefits include high precision, versatility in cutting various metals, efficiency, minimal material waste, and the ability to create custom products.

What challenges might businesses face with laser cutting services?

Challenges include high initial investment, ongoing maintenance and repair costs, the need for skilled operators, staying updated with technology, and competition in the market.

What legal and regulatory aspects should be considered?

Businesses must comply with safety standards, environmental regulations, proper material handling practices, and obtain necessary permits for industrial operations.

How can businesses effectively market their laser cutting services?

Effective marketing strategies include showcasing the precision and quality of services, targeting niche markets, building a strong online presence, emphasizing customization, and networking with industry professionals.

What are the future trends in laser cutting of metals?

Emerging trends include increased automation, the development of advanced materials, a focus on eco-friendly practices, the integration of AI and machine learning, and growing demand for customization and personalization in metal products.

If you enjoyed this article and found it valuable, we encourage you to explore our news and valuable information section, where you'll find more relevant and up-to-date content that may pique your interest. Additionally, if you are seeking advice or need guidance on a specific topic, we suggest visiting our services section. There, you will find a variety of options designed to assist and support you in addressing your needs. Feel free to check out both sections to get the information and assistance that best suits your requirements.

Leave a Reply