Exploring the Business Idea of Candle Pouring Dispensers

- Exploring the Business Idea of Candle Pouring Dispensers

- What is a Candle Pouring Dispenser?

- Market Opportunities for Candle Pouring Dispensers

- Initial Costs of Starting a Candle Business

- Unique Selling Points of Candle Pouring Dispensers

- Steps to Scale Up Candle Production

- Legal and Regulatory Requirements for Candle Businesses

- Packaging and Branding for Candles

- Potential Challenges in Candle Making

- Customer Feedback and Product Improvement

- Future Trends in Candle Making

-

FAQ

- What types of candles can be made with a pouring dispenser?

- How long does it take for wax to melt using a candle pouring dispenser?

- Can I use any type of wax with a candle pouring dispenser?

- How do I clean and maintain my candle pouring dispenser?

- What are some common mistakes to avoid when using a candle pouring dispenser?

- Can I start a candle business with just a pouring dispenser?

- What are the benefits of using a candle pouring dispenser compared to manual pouring?

Exploring the Business Idea of Candle Pouring Dispensers

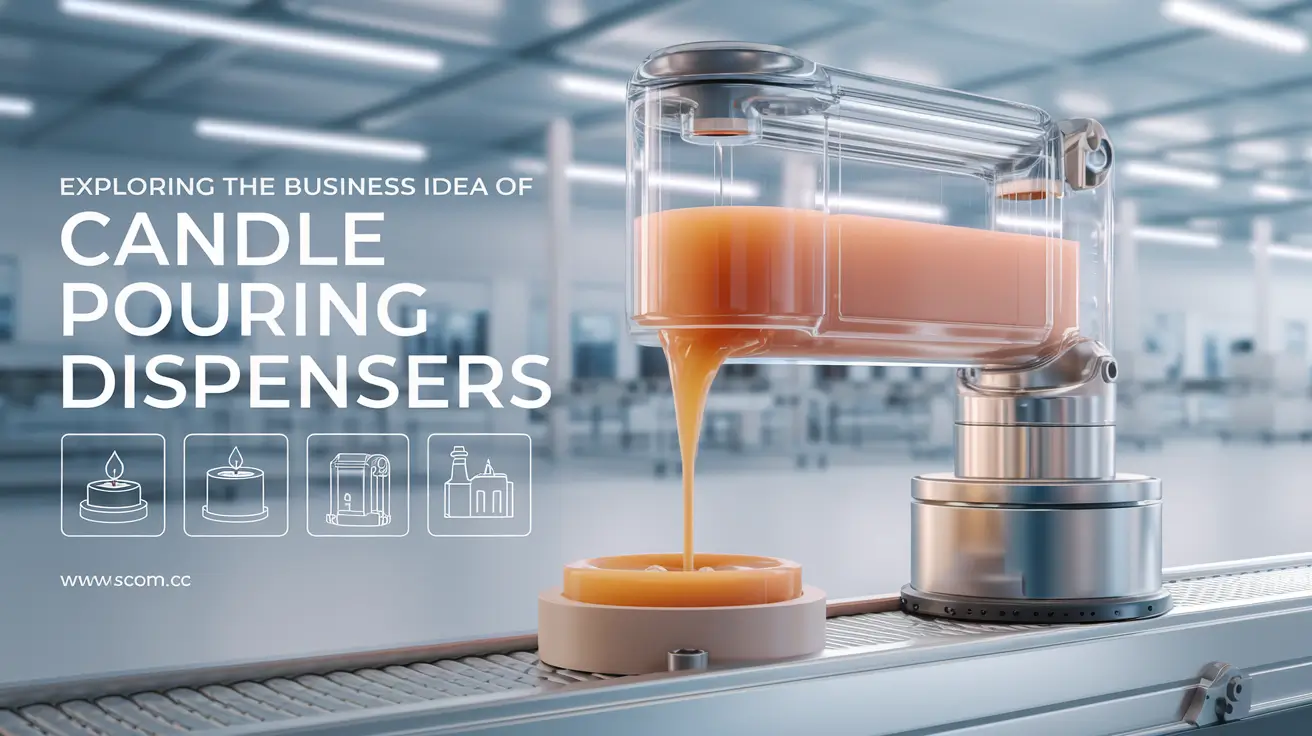

What is a Candle Pouring Dispenser?

A candle pouring dispenser is a specialized tool designed for melting and pouring wax into various candle molds. This device streamlines the candle-making process, allowing for precise control over the pouring temperature and consistency. Ideal for artisanal candle makers, a candle pouring dispenser offers versatility in creating candles of different sizes and shapes.

How It Works

- Wax Melting: The dispenser heats the wax to the desired temperature for pouring.

- Temperature Control: Maintains a consistent temperature to ensure the wax flows smoothly and sets properly.

- Pouring Mechanism: Features a controlled dispensing system that allows for accurate pouring into molds.

- Versatility: Can be adjusted to accommodate different mold sizes and shapes.

Types of Candle Pouring Dispensers

- Manual Dispensers: Require manual control for pouring; suitable for small-scale operations.

- Electric Dispensers: Feature automatic temperature control and a more efficient pouring mechanism; ideal for larger-scale production.

Market Opportunities for Candle Pouring Dispensers

The market for candle pouring dispensers is driven by the growing popularity of artisanal and handmade candles. Understanding market opportunities and targeting specific segments can help in positioning your product effectively.

Target Markets

- Artisanal Candle Makers: Individuals or businesses focused on creating handcrafted candles with unique designs and scents.

- Craft Stores: Retailers specializing in craft supplies and materials for candle-making enthusiasts.

- Home Decor Shops: Stores offering customized and decorative candles as part of their product range.

Market Trends

- Personalization: Increasing demand for personalized and customized candles drives the need for versatile pouring equipment.

- Sustainability: Growing interest in eco-friendly and sustainable candle materials influences the choice of equipment and production methods.

- Online Marketplaces: Rising popularity of online platforms for selling handmade candles expands market reach.

Initial Costs of Starting a Candle Business

Starting a candle business involves an initial investment in equipment, materials, and other essential components. The costs can be relatively affordable compared to other business ventures, making it an attractive option for entrepreneurs.

Breakdown of Initial Costs

- Candle Pouring Dispenser: Costs start from $300, depending on features and capacity.

- Wax and Fragrance Oils: Includes the cost of wax, fragrance oils, and any additives. Estimated cost: $100-$300.

- Molds and Containers: Purchase molds and containers for different candle shapes and sizes. Estimated cost: $50-$150.

- Packaging and Labeling: Invest in packaging materials and labels for your finished candles. Estimated cost: $50-$200.

Cost Estimates

| Expense | Estimated Cost |

|---|---|

| Candle Pouring Dispenser | $300-$1,000 |

| Wax and Fragrance Oils | $100-$300 |

| Molds and Containers | $50-$150 |

| Packaging and Labeling | $50-$200 |

| Total Estimated Cost | $500-$1,650 |

Additional Considerations

- Marketing Costs: Budget for promoting your products and reaching potential customers.

- Workspace Setup: Consider the cost of setting up a dedicated workspace for candle production.

Unique Selling Points of Candle Pouring Dispensers

Candle pouring dispensers offer several unique selling points that can help differentiate your product in the market. Highlighting these features can attract customers and enhance your business’s appeal.

Key Selling Points

- Precision: Provides accurate temperature control and pouring, ensuring high-quality candles.

- Versatility: Accommodates various mold sizes and shapes, allowing for diverse candle designs.

- Efficiency: Streamlines the candle-making process, saving time and reducing waste.

Product Differentiation

- Customizable Features: Offer dispensers with adjustable settings and accessories to meet different production needs.

- Build Quality: Ensure durability and reliability in the design and materials of the dispenser.

Marketing Messaging

Emphasize the precision, versatility, and efficiency of your candle pouring dispenser in your marketing materials. Highlight how it can enhance the candle-making process and improve the quality of the final product.

Steps to Scale Up Candle Production

Scaling up your candle business involves expanding production capacity, reaching new markets, and improving operational efficiency.

Scaling Strategies

- Invest in Advanced Equipment: Upgrade to larger or multiple dispensers to handle increased production volumes.

- Expand Distribution Channels: Explore new sales channels, such as online marketplaces and retail partnerships.

- Increase Production Efficiency: Streamline operations and optimize production processes to meet growing demand.

Key Considerations

- Quality Control: Maintain consistent quality as production scales up to ensure customer satisfaction.

- Staffing: Hire additional staff to manage increased production and customer service.

Investment Needs

- Capital: Additional investment may be required for new equipment, materials, and marketing efforts.

- Training: Invest in training for staff to operate advanced equipment and manage larger-scale operations.

Legal and Regulatory Requirements for Candle Businesses

Operating a candle business involves adhering to various legal and regulatory requirements to ensure compliance and protect your business.

Key Requirements

- Business Licensing: Obtain necessary licenses and permits for operating a candle-making business in your area.

- Health and Safety Regulations: Follow regulations related to workplace safety, especially when working with hot wax and other materials.

- Product Safety: Ensure compliance with product safety standards and labeling requirements for candles.

Compliance Checklist

- Business Registration: Register your business and acquire any required permits or licenses.

- Safety Protocols: Implement safety measures for handling and storing wax and other materials.

- Labeling: Adhere to regulations for labeling candles, including ingredient lists and safety warnings.

Packaging and Branding for Candles

Effective packaging and branding are crucial for attracting customers and establishing a professional image.

Packaging Options

- Protective Packaging: Use packaging that protects candles during shipping and handling.

- Custom Packaging: Consider custom packaging designs to enhance the presentation and appeal of your candles.

Branding Strategies

- Logo and Design: Develop a memorable logo and brand identity that reflects the quality and uniqueness of your candles.

- Marketing Materials: Create brochures, business cards, and other marketing materials that showcase your products.

Cost Considerations

- Packaging Costs: Invest in quality packaging materials that align with your branding and protect your products.

- Design Costs: Allocate budget for professional branding and design services.

Potential Challenges in Candle Making

Running a candle-making business can present several challenges, which require proactive solutions to overcome.

Common Challenges

- Consistency: Achieving consistent quality and appearance in candles can be challenging.

- Market Competition: Competing with other candle makers and large retailers can be tough.

- Production Efficiency: Scaling up production while maintaining quality requires careful planning and management.

Solutions

- Quality Control Measures: Implement strict quality control processes to ensure consistency.

- Market Research: Conduct research to identify opportunities and differentiate your products.

- Efficient Processes: Optimize production processes to improve efficiency and reduce waste.

Customer Feedback and Product Improvement

Gathering and implementing customer feedback is essential for refining your products and enhancing customer satisfaction.

Feedback Collection Methods

- Surveys: Use surveys to gather feedback on customer preferences and experiences.

- Focus Groups: Conduct focus groups to test new candle designs and obtain detailed feedback.

- Online Reviews: Monitor online reviews to identify common themes and areas for improvement.

Implementing Feedback

- Product Enhancements: Make adjustments to your candles based on customer feedback to better meet their needs and preferences.

- Service Improvements: Address any issues related to customer service and delivery to improve overall satisfaction.

Future Trends in Candle Making

Staying informed about future trends can help you adapt and innovate in the candle-making industry.

Emerging Trends

- Sustainable Practices: Increasing interest in eco-friendly and sustainable candle materials and production methods.

- Customization: Growing demand for personalized and unique candles, including custom scents and designs.

- Technology Integration: Advancements in candle-making technology and tools to enhance production efficiency and creativity.

Adapting to Trends

- Invest in Sustainability: Explore sustainable materials and practices to appeal to environmentally conscious consumers.

- Offer Customization: Provide options for personalized candles to meet evolving customer preferences.

- Embrace Technology: Stay updated on technological advancements and consider integrating new tools into your production process.

Summary Table

| Topic | Key Points |

|---|---|

| What is a Candle Pouring Dispenser? | A tool for melting and pouring wax into molds; offers precision and versatility. |

| Market Opportunities | Target markets include artisanal candle makers, craft stores, and home décor shops; driven by personalization and sustainability trends. |

| Initial Costs | Costs range from $300 to $1,650; includes dispenser, wax, molds, packaging, and labeling. |

| Unique Selling Points | Precision, versatility, and efficiency in candle-making; differentiate with customizable features. |

| Scaling Up | Invest in advanced equipment, expand distribution channels, and improve production efficiency; requires additional capital and training. |

| Legal Requirements | Obtain business licenses, follow health and safety regulations, and ensure product safety compliance. |

| Packaging and Branding | Use protective and custom packaging; develop a memorable brand identity and marketing materials. |

| Potential Challenges | Consistency, market competition, and production efficiency; solutions include quality control and process optimization. |

| Customer Feedback | Collect through surveys, focus groups, and reviews; implement feedback to improve products and services. |

| Future Trends | Sustainable practices, customization, and technology integration; adapt by exploring new materials and tools. |

FAQ

What types of candles can be made with a pouring dispenser?

A pouring dispenser can be used to make various types of candles, including pillar candles, votive candles, container candles, and tapered candles. The versatility of the dispenser allows for different sizes and shapes.

How long does it take for wax to melt using a candle pouring dispenser?

The time it takes to melt wax depends on the type of wax, the dispenser’s heating capacity, and the amount of wax. Generally, it can take anywhere from 15 to 30 minutes to melt wax to the desired temperature.

Can I use any type of wax with a candle pouring dispenser?

Most candle pouring dispensers are compatible with a range of wax types, including paraffin, soy, beeswax, and palm. It is important to follow the manufacturer’s guidelines for the specific wax type you plan to use.

How do I clean and maintain my candle pouring dispenser?

Regular cleaning and maintenance involve removing any residual wax, checking for wear and tear, and ensuring the heating element is functioning properly. Follow the manufacturer’s instructions for cleaning and maintenance procedures.

What are some common mistakes to avoid when using a candle pouring dispenser?

Common mistakes include using wax at incorrect temperatures, overfilling molds, and not allowing candles to cool properly before removing them from molds. Following proper techniques and guidelines can help avoid these issues.

Can I start a candle business with just a pouring dispenser?

While a pouring dispenser is a crucial tool, starting a candle business also requires other equipment and materials, such as wax, molds, packaging, and labeling supplies. Additionally, consider marketing and distribution strategies.

What are the benefits of using a candle pouring dispenser compared to manual pouring?

A candle pouring dispenser offers benefits such as precise temperature control, efficient and consistent pouring, and the ability to handle larger quantities of wax. This results in higher quality candles and a more streamlined production process.

If you enjoyed this article and found it valuable, we encourage you to explore our news and valuable information section, where you'll find more relevant and up-to-date content that may pique your interest. Additionally, if you are seeking advice or need guidance on a specific topic, we suggest visiting our services section. There, you will find a variety of options designed to assist and support you in addressing your needs. Feel free to check out both sections to get the information and assistance that best suits your requirements.

Leave a Reply